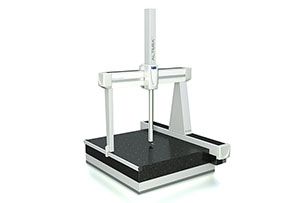

Three-coordinate, two-element, three-dimensional measuring instruments, image measuring instruments, etc. are commonly used measuring equipment, so what is the difference between the three-dimensional measuring instrument and the second element?

As a precision inspection instrument, the measurement direction of the three-dimensional measuring instrument is XYZ axis (three directions of horizontal and vertical height), and the measurement direction of the secondary element is X/Y axis (horizontal longitudinal direction). Generally, the coordinate measuring instrument is a pneumatic device. The accuracy will be higher than the second element (the second element is also pneumatic, but the price is much higher), its price and weight are also higher than the second element. The price of the ordinary mechanical guide element is about 30,000 to 50,000. At around 200,000, the three-dimensional measuring instrument is more expensive.

Three-dimensional measuring instruments are used in many areas, and many parameters of the workpiece can also be measured. We know that the secondary image measuring instrument can also easily detect the three-dimensional parameters of the workpiece after adding the probe. What is the difference between the three-coordinate measuring instrument and the two-dimensional image measuring instrument plus the probe? The difference is three-dimensional. In addition to simple three-dimensional measurement of length, width and height, the measuring instrument can also measure complex surfaces of workpieces.

Xinli Precision Machinery provides a variety of professional measurement solutions, sales of three coordinates, three yuan, altimeter, profiler, three coordinate measuring machine, three-dimensional measuring instrument, image measuring instrument, online machine testing equipment, etc., welcome to consult.