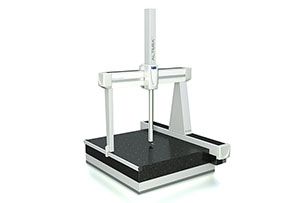

The three-dimensional measuring instrument is a high-precision measuring instrument, which determines the important factors of high precision. In addition to the design of the three-dimensional measuring instrument itself, the selection and use of the stylus is not negligible. Below, Xiaobian will introduce you to the stylus selection guide.

In order to maintain the accuracy of the contact point, the recommendations for selecting the stylus for the three-dimensional measuring instrument are as follows:

1. Select a short stylus as much as possible: because the longer the stylus is bent or the larger the amount of deformation, the lower the accuracy;

2. Minimize the number of stylus components: each additional stylus is connected to the stylus bar, adding a potential bending and deformation point;

3. Try to use the stylus with the larger diameter of the ball as much as possible: First, it can increase the distance of the ball/stylus, thus reducing the false trigger caused by the collision of the stylus; secondly, the larger the diameter of the ball, The effect of the surface roughness of the workpiece to be tested is smaller.

For different workpiece features, it is recommended that customers choose different types of styli:

Straight stylus:

Straight stylus is the simplest type of stylus for most probe applications. Straight shoulder and tapered probes are available. When the workpiece is easily accessible, the stylus with the tapered rod is more rigid. The stylus ball head is made of ruby, silicon nitride, zirconia, ceramic or tungsten carbide.

For most applications, the ruby ball is the default option for styli, while in the scanning probe, for cast iron and aluminum workpieces, we prefer the side balls of alumina and silicon nitride.

Star stylus:

Star styli can be used to measure a variety of different body structures, such as surfaces and holes that can be directly contacted and complex internal contours. When using a star stylus to detect extreme points of internal features such as sides or grooves in a hole, there is almost no need to move the probe due to the multi-tip detection capability.

Disc type stylus:

The disc type stylus is a "section" of the high sphericity ball, available in a variety of diameters and thicknesses. Disc stylus mounted on the plug

Upper, made of steel, ceramic or ruby. The omnidirectional rotation adjustment and the addition of the center stylus are features of the disc stylus series. These types of styli are mainly used to detect the undercut and groove in the hole that the star stylus cannot reach.

Columnar stylus:

It is used to measure metal sheets, molded parts and thin workpieces that cannot be accurately contacted by spherical styli. It can also measure various thread features and position the center of the tapping hole. The cylindrical end of the cylindrical stylus can be fully calibrated and measured in X, Y and Z directions, so surface measurements can be made.

Ceramic hemispherical stylus:

The ceramic hemispherical stylus has a large diameter and a very small weight, which is mainly used to measure deep features and holes. It is also suitable for contact with rough surfaces because the roughness is mechanically filtered out by the large diameter surface.

Stylus extension rod:

The stylus extensions are made of steel, titanium, aluminum, ceramic and carbon fiber and are used to measure extremely deep features and holes, or to measure points that are difficult to reach.