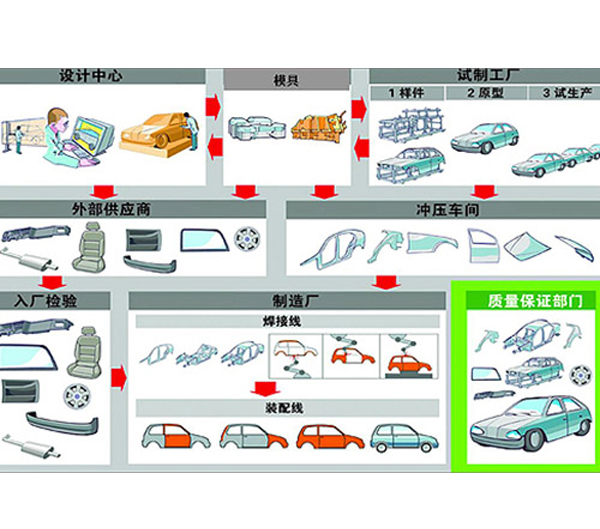

Automobile cover mould is the most typical type of automobile mould, and it is also the representative type of stamping die. It has strict requirements on measurement technology in its fields of processing, research, trial production, and parts. This includes the preparation of casting blanks, processing and testing of complex profiles, mold trials and mold clamping analysis. In view of the large size and complex shape of stamping dies, more on-site measuring systems are required to penetrate, process, manufacture and assemble. The whole process of test mold clamping and even part measurement and copy repair.

01 casting processing

The processing of stamping die blank castings is currently popular for lost foam processing, that is, using soft materials such as sludge, resin, and plastic foam to form a lost foam mold. The traditional lost foam machining method is an engraving machine or a heavy-duty CNC machining machine. These machining solutions have limitations in processing size, need to fix the foundation, and have large investment. The ROMOCUT flexible robotic milling system overcomes the above-mentioned drawbacks: it can be moved, does not require foundation and machine room, can realize multi-position movement processing to achieve unlimited expansion of high-precision machining range, and can also be equipped with hollow milling cutter and vacuum chip removal for plastic foam material. The system ensures a clean and pollution-free processing environment. ROMOCUT is a new generation replacement for traditional lost foam milling systems.

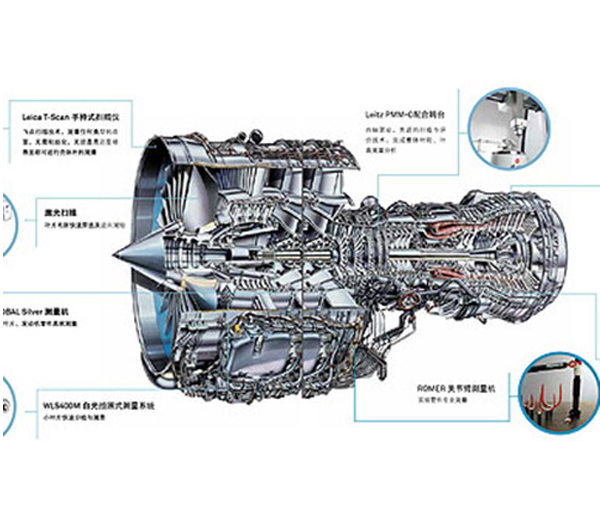

02 on-site measurement

In the stamping die processing stage, the most efficient measurement solution is the first to push a portable on-site measurement solution – an articulated arm that can be measured at startup, flexible and suitable for hidden point measurement, and has the advantage of acquiring curved point clouds with high efficiency and large area. Photographic measurement systems and laser trackers that win with high-precision, large-size measurement ranges, of course, include on-machine measurement solutions that provide real-time feedback of machining results in the process. The advantage of the on-site measurement solution is the ability to provide timely reference data for the efficient visualization of molds www.3eeezw.com.

03 test mode

Through the analysis of the mold clamping of the concave and convex mold and the analysis of the shape and springback of the prototype, the mold is adjusted and modified to obtain the correct shape of the workpiece. The large-scale curved shape is a remarkable feature of the stamping die and its parts. Therefore, the comparison between the die-type point cloud and its CAD is the most efficient data analysis method. The CognitensWLS400 camera-based measurement system enables high-speed acquisition of single large-area, high-precision point clouds in demanding industrial environments that are immune to vibration and illumination, and data processing such as virtual assembly and batch data statistical analysis for point clouds. CognitensWLS400 can complete multiple inspection tasks in various parts of molds, tooling and parts, and can be used for quality control of the whole process from mold processing to delivery.

04 precision measurement

The mold frame of the stamping die is a component that transmits pressure and ensures the positional accuracy of the die. The positional precision of the upper guide post, the guide bush and the guide pin are required to be high. The universal precision measuring equipment is a fixed (bridge, gantry, cantilever) measuring machine that can perform high-precision quality verification. The DEA gantry measuring machine adopts an open structure and a foundation-type platform, which is not limited by load bearing, and is convenient for the large stamping die to be placed and loaded.

05 equipment adjustment

When stamping a part with a stamping die, it is usually necessary to perform precision correction on the processing equipment. The Leica Absolute Tracker is the ideal solution for aligning, installing and calibrating large equipment. With the unique PowerLock automatic target locking function, the Leica Absolute Tracker is capable of precision alignment and inspection up to 160m in a complex workshop environment with a reflective ball.

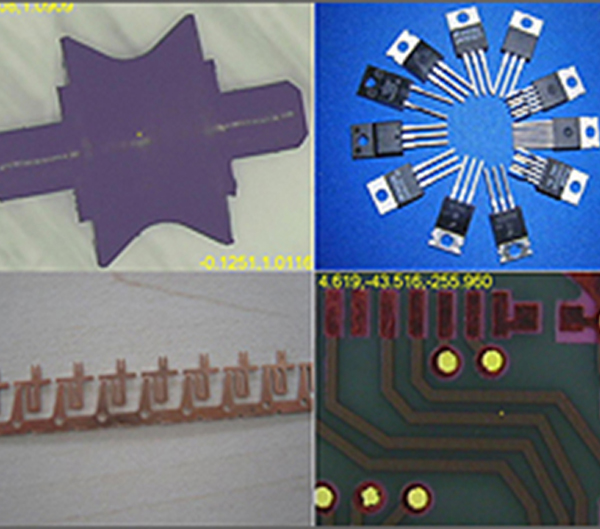

06 parts inspection

Verification of the position and shape of the stamping part will determine whether the mold can be delivered, and the rapid and repeatable data acquisition and evaluation of the stamped surface is the key to complete the measurement and analysis of the part. The fixed measuring system (bridge, gantry, cantilever measuring machine) equipped with the new CMS series laser scanner enables automatic and efficient inspection of stamped parts surfaces. CMS has good adaptability such as automatic exposure, can adapt to various materials of different materials and colors, different brightness, variable line width, variable point distance intelligent features, making the workpiece surface point cloud more efficient. The high-paced on-site quality control of the mature parts production line can be automated with the CognitensWLS400A robotic camera.

07 inspection tool

The inspection tool is the inspection standard for large-volume parts on the production line. According to the different precision requirements of the inspection tool, fixed measuring equipment or portable field measuring equipment can be selected.

08 copy and repair

Successfully delivered molds need to be archived, and finished molds in use need to be quality controlled at any time to repair wear or copy. The Cognitens photogrammetric system and the ROMER absolute articulated arm with high-efficiency laser scanning probes enable efficient acquisition of mold point cloud data, CAD data comparison analysis, or assisted reverse modeling.

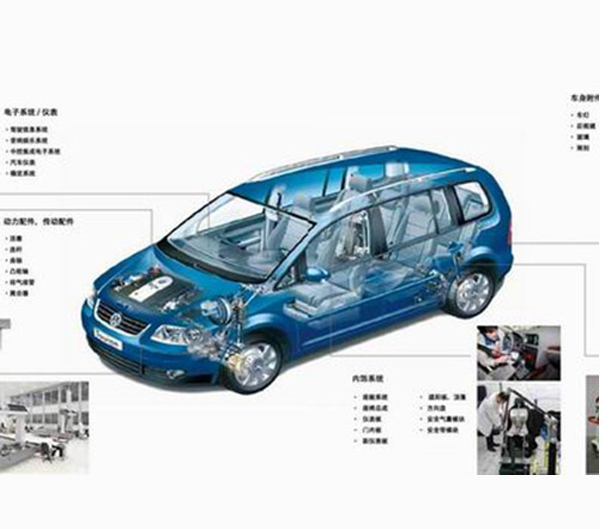

Fixture

In the welding process of the automobile, since the rigidity of the thin plate member is easily deformed, in order to ensure the correct relative position and the welding gap between the components, it must be fixed by the welding fixture. Therefore, the accuracy of the welding fixture is an important means to determine the accuracy of the body geometry.

Automobile fixtures, especially welding fixtures, have the characteristics of large size and complicated application environment, and often involve tasks such as daily maintenance, maintenance and adjustment of the production line. Therefore, a set of measurement scope is large, flexible, and suitable for complex environments on site. The measurement system is an important factor in ensuring the quality of the fixture.

The Leica Laser Tracker is the ideal solution for on-site portable measurements in oversized workshops. With a reflective ball, the system can achieve a large measurement range of 320m; with a T-type probe, a 30m higher precision measurement range can be obtained, and an extra long extension rod can be equipped to complete the hidden point measurement. Leica laser tracker is widely used in the installation and positioning and precision maintenance of automotive welding fixtures on the shop floor.

Check tool

The inspection tool is an abbreviation for product parts inspection fixtures such as stamping parts and injection molding parts. It is a kind of inspection tool specially made according to the specific requirements of the buyer. The size, position and shape of the gage need to be rigorously measured to determine that it can be used as a test basis for high volume parts on the production line.

In many cases, some large-sized gages have the characteristics of large size and weight, which are inconvenient to move. Therefore, a portable measuring system is often required to provide a portable measuring means for the manufacture of the gage.