-

-

Fixed line:0769-2161189513412498689

24Hour consultation hotline

-

-

13412498689@163.COM

24Hour consultation hotline

-

-

No. 3A07, Building C, Yesheng Business Center, No. 2 Zhen'an East Road, Zhenbian East Road, Chang'an Town, Dongguan City

- Home

- About us

-

CMM

- Bridge type coordinate measuring machine

- Articulating arm coordinate measuring instrument

- Gantry large-scale three coordinate measuring machine

- Single horizontal arm desktop coordinate measuring machine

- Double horizontal arm desktop coordinate measuring machine

- Single cantilever coordinate measuring machine

- Double cantilever coordinate measuring machine

- Double bridge gantry measuring instrument measuring machine

- Non-contact coordinate measuring machine

- Contact coordinate measuring machine

-

Swiss TESA

- Altimeter

- Inner diameter table

- Surface roughness measuring instrument

- Height caliper

- Portable surface roughness

- Depth Gauges

- Contour measuring instrument

- Digital height caliper

- Small surface roughness measuring instrument

- Cursor height caliper

- Desktop surface roughness measuring instrument

- Reference gauge

- CNC surface roughness measuring instrument

- Digital display

- Caliper

- Pointer indicator

- Caliper with table

- Dial indicator

- Digital caliper

- Dial indicator

- Nikon

-

Products

- CMM

-

- Bridge type coordinate measuring machine

- Articulating arm coordinate measuring instrument

- Gantry large-scale three coordinate measuring machine

- Single horizontal arm desktop coordinate measuring machine

- Double horizontal arm desktop coordinate measuring machine

- Single cantilever coordinate measuring machine

- Double cantilever coordinate measuring machine

- Double bridge gantry measuring instrument measuring machine

- Non-contact coordinate measuring machine

- Contact coordinate measuring machine

- Sanfeng measuring instrument

-

- Altimeter/altimeter

- Digital internal diameter micrometer

- Lever indication table

- Outside diameter micrometer

- Dial indicator

- Inner diameter micrometer

- Dial indicator

- Micrometer

- Electronic indicator

- Inner diameter table

- Dial indicator

- Height caliper

- Precision indicator

- Depth Gauges

- Magnetic table

- Digital height caliper

- Radius gauge

- Cursor height caliper

- Secondary element

- Reference gauge

- 2.5 dimensions

- Digital display

- Three-dimensional composite measuring instrument

- Pointer indicator

- Swiss TESA

-

- Altimeter

- Inner diameter table

- Surface roughness measuring instrument

- Height caliper

- Portable surface roughness

- Depth Gauges

- Contour measuring instrument

- Digital height caliper

- Small surface roughness measuring instrument

- Cursor height caliper

- Desktop surface roughness measuring instrument

- Reference gauge

- CNC surface roughness measuring instrument

- Digital display

- Caliper

- Pointer indicator

- Caliper with table

- Dial indicator

- Digital caliper

- Dial indicator

- Electronic indicator

- Digital internal diameter micrometer

- Dial indicator

- Outside diameter micrometer

- Precision indicator

- Inner diameter micrometer

- Magnetic table

- Micrometer

- Radius gauge

-

Solution

- medical instruments

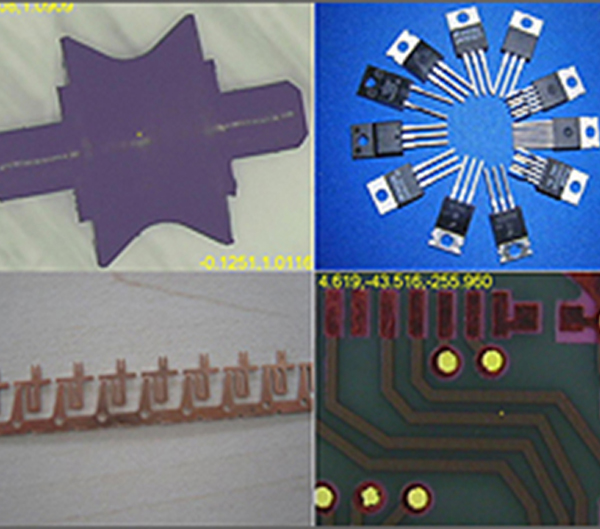

- electronic

- General equipment manufacturing

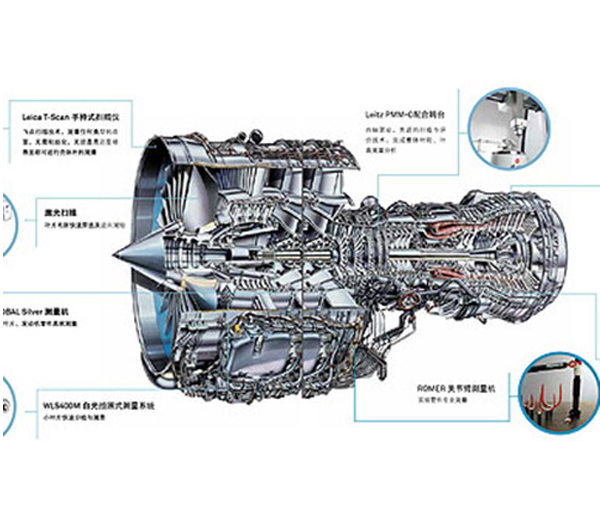

- Aerospace: Engine Factory

- Aerospace: OEM

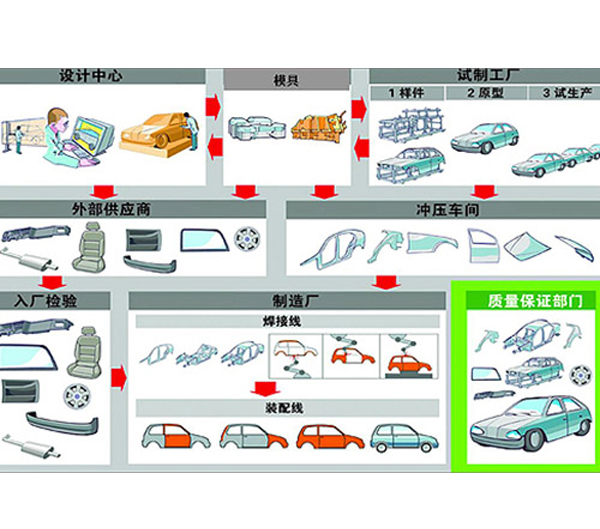

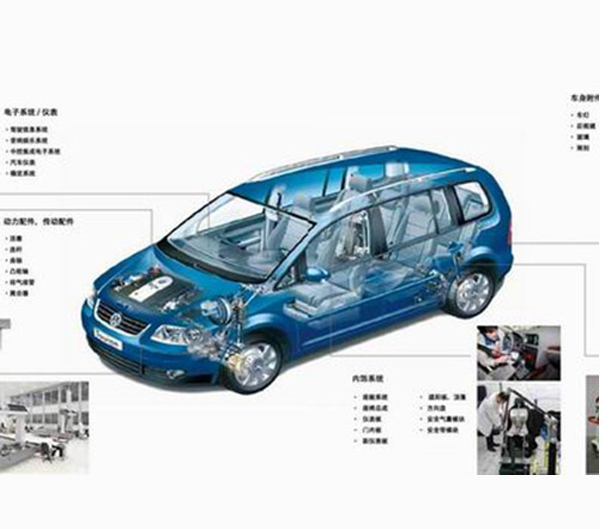

- Car: body and sub-assembly

- car parts

- Car: Powertrain

- Car: mold, fixture, inspection tool

- Car: Auto Research

- Machine tool online measurement

- Machining center programming knowledge

- Online measurement

- Mold equipment

- Automated measurement

- Machining center operating procedures

- service support

- News

- Contact us

0769-21611895

134-1249-8689